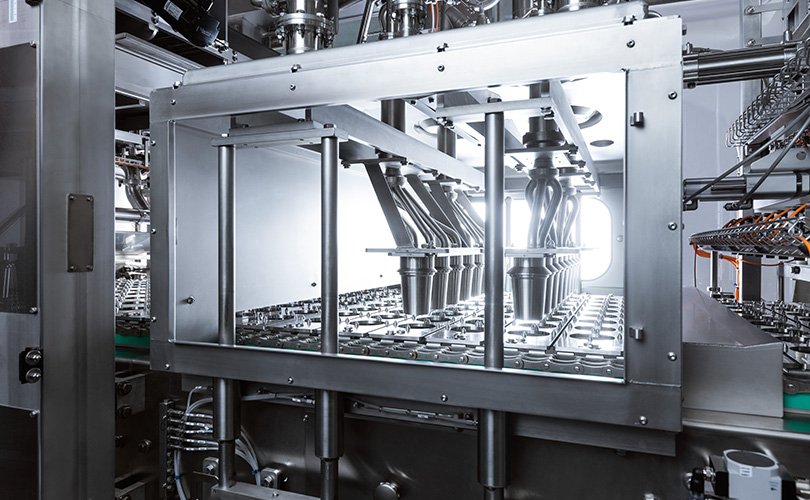

Filling machine

Reliably filling products with different consistencies requires precise filling systems with state-of-the-art filling technology. These systems ensure that liquids, powders, pastes or piecemeal products are perfectly portioned and efficiently filled into cups, glass jars, bottles, tubs, tubes or pouches.

Every filler machine must match the characteristics of the product to guarantee efficiency and precision in large batches. Whether it’s food, pet food, cosmetics or pharmaceuticals – your Waldner filling machine is designed around your process. You define the performance, we deliver the machinery that meets your exact needs.

Unique products call for tailored solutions: that’s why the size, technical equipment and operation of our filling systems can be adapted with utmost flexibility. Waldner filling machines are configured to suit the filling substance and container down to the smallest detail and equipped with cutting-edge filling technology to enable precise, efficient filling – while complying with the most stringent hygiene standards at all times.

Regardless of whether you need a liquid filling machine, a solution for powders or pastes, a semi-automatic or fully automatic filling system – we will equip your machine with all your desired functions, which can be individually monitored and controlled.

Yoghurt, cream cheese, fruit jams, minced meat, delicatessen specialities – filling machines have a wide range of applications in the food industry. But not every filling machine is equally suitable for every product: filling fruit syrup into bottles, for example, requires different filling mechanisms than those used for portioning potato salad into cups.

The consistency of the filling substance and the container to be filled (e.g. cup, bottle or pouch) are the two main factors for the individual configuration of your filling system. In the food sector, there are also strict hygiene regulations that must be complied with to avoid germs and contamination. Packaging sterilisation processes for impeccable food hygiene are therefore standard in our systems.

Have you already crafted the perfect recipe for your pet food and now just need the right solution for filling? Then the pet food filling machines from Waldner are just what you’ve been looking for. Our systems can be individually adjusted to the different consistencies of wet and dry food, enabling even and hygienic filling into cans, bowls and pouches.

A stand-out solution is our pouch packing machine for pet food, which can fill up to 30,000 pouches per hour with accuracy down to the gram. Thanks to the optional two-phase filling system, it’s even possible to precisely dose pet food of differing consistencies (e.g. pieces and gravy) in one pouch – always in line with the highest hygienic standards.

The cosmetics sector typically involves liquid, powdery or paste products that need to be filled into a wide variety of packaging. One challenge is that a single product often has to be filled into different container types. Whether it’s jars and tubes of crème or different sizes of shampoo bottle – a filling system for cosmetics needs to be able to handle anything.

Cosmetic products are constantly evolving, and several formulations are often processed by a single machine. It is therefore vital that filling machines can be thoroughly cleaned. This avoids undesired residues and guarantees uncontaminated products.

When chemicals such as cleaning agents, laundry detergents, pesticides or fertilisers are processed in a liquid filler machine, two challenges arise. First, large packaging formats are often required – such as bottles, tubs, canisters and sometimes even barrels – which presents a logistical challenge for the filling machinery.

Second, the dosing and filling method must take the specific chemical properties into account, since these products often need to be filled extremely gently and with millimetre or gram accuracy. Furthermore, the safety of the production employees must be guaranteed whenever hazardous substances are handled.

Let’s work together to create a unique, ideal filling solution for your products.

All our filling systems are based on the Waldner DOSOMAT, which can be adjusted to all customer-specific requirements – whether you’re looking for a large liquid filling machine for bottles, a compact solution for cups or an especially flexible model for different kinds of packaging.

On request, the DOSOMAT can also combine filling and packaging in one machine. This means precise dosing, reliable sealing and careful packaging are handled by a single system – increasing efficiency and reducing potential errors.

Available variants:

The DOSOMAT inline system is a fully automatic, high-performance machine for gentle filling into prefabricated cups (plastic, aluminium, cardboard, steel, glass) or stand-up pouches. Suitable for products such as muesli, pet food, powders or fruit.

The DOSOMAT rotary system is a highly flexible all-rounder with a space-saving design and variable output range of 2,500–30,000 cups per hour. Ideal for both liquid filling and portioning of viscous, powdery or chunky products.

Our filling machines are produced in a modular design. The basic model is supplemented with the desired equipment options. All parts that come into contact with the product are made of high-alloy stainless steel (DIN 1.4404 or AISI 316 L) or food-safe plastics.

Matching filling valves are available for each filling machine:

To securely close the filled product, Waldner filling machinery can be equipped with various sealing options – depending on the product and container.

A hygienically clean container is essential for a long product shelf life. Depending on the requirements, Waldner implements one of the following options for cup and lid sterilisation:

Our filling systems can be equipped with the following drives:

Combinations of these drive types are also possible.

Let’s work together to create custom-made filling machinery tailored to your products.

In our long history of manufacturing filling systems, Waldner has supported customers in a wide range of industries. Our tailored solutions increase efficiency, safety and speed in automatic filling processes. Get in touch with us and we will design the perfect filling machine for your product, too.

To expand your filling line, discover more systems and skids from Waldner, or supplement your production site with products like:

You might also be interested in