A laboratory fume hood for maximum safety and efficiency

A laboratory fume hood (also known as a fume cupboard or fume closet) protects the people who work in laboratories with its safe ventilation. It helps to prevent the release of substances harmful to health into the environment and acts as a safe barrier between humans and experimental set-ups. We strive to advance these standards, optimising the airflow rate and saving up to 33% energy, thanks to Secuflow technology.

A laboratory fume hood from Waldner also impresses with its innovative optional functions, including height adjustment, intelligent details, and digital connectivity. Waldner offers the right fume hood for every application, whether you require a bench-mounted fume hood or a walk-in fume hood, have specific requirements governing the internal lining, or require an explosion-proof design.

Secuflow Vision – the Innovative Waldner Lab Fume Hood

Fume Hood – Safety as a Prerequisite

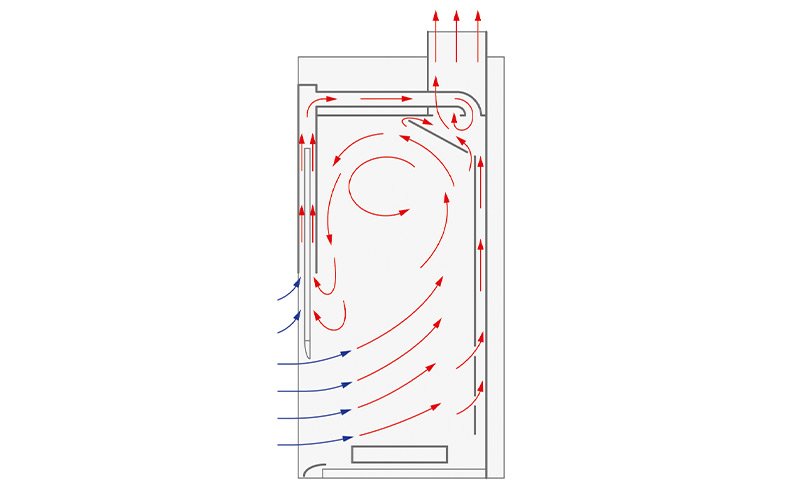

Ensuring stringent safety in laboratories is paramount. Waldner's lab fume hoods are meticulously engineered to minimize the risk of backflows from the interior of the chemical fume hood, thereby avoiding the escape of harmful substances. Their aerodynamic design enhances airflow, ensuring smooth air movement and reducing turbulence.

Supportive flow air is directed over the airfoil cills, avoiding turbulence and effectively flushing harmful gases away from side walls and work surfaces. The Secuflow fume hood maintains outstanding retention values, even with densely packed equipment in the interior or significant activity in front of it. Its performance surpasses the standards set by DIN EN 14175 and ASHRAE 110, providing reliable protection for laboratory personnel.

Safety equipment for your laboratory fume hood

To make your fume hood and laboratory even safer, we have developed various safety features. They protect the people in the laboratory as well as the experimental set-up inside the fume cupboard. We offer the following options:

In the pharmaceutical industry, work often involves particulate matter and aerosols. Electrostatic charges near surfaces can cause particles to adhere and be transferred via clothing and equipment. Waldner's IONIC technology employs high-voltage electrodes to ionize the supportive flows, discharging the particulate matter and aerosols, enabling safe flushing by the laboratory fume hood.

A motion sensor on the laboratory fume hood detects whether a person is working at the fume hood. If not, the fume hood automatically closes the open sash. This increases safety and maximises energy efficiency, as the required extract air volume can be reduced to a minimum.

A light barrier monitors the automatic sash-closing process. If an obstacle projects from the internal workspace or a hand is detected within the light barrier's sensing area, the closing process stops. This feature prevents damage to the experimental setup.

The front sash and, optionally, the horizontal sashes are continuously monitored. If the lab fume hood detects that a sash remains open, it emits both visual and audible alarms.

Cameras and temperature sensors can be used to remotely monitor laboratory experiment setups. In critical situations, an alarm can be transmitted to the building management system, enabling continuous monitoring of processes within the laboratory fume cupboard.

Fume hoods designed for special applications with high thermal loads and/or exposure to acids must meet stringent requirements in accordance with DIN EN 14175-7. In specific models, we have adapted the airflow design to ensure laminar flow and safe extraction, even when working with high heat sources (e.g., hot plates). The use of specialized chemical fume hoods and appropriate materials also enables safe handling of perchloric and hydrofluoric acids.

Your Fume Hood, Your Custom-Made Solution

Let Waldner experts guide you in finding the perfect fume hood solution for your laboratory.

Greater Energy Efficiency with Secuflow Laboratory Fume Hoods

In continuous laboratory operation, a standard fume hood consumes approximately the same amount of energy annually as a single-family home. Consequently, laboratory ventilation typically accounts for a significant portion of operating costs. However, this is not the case with Secuflow laboratory fume hoods.

Secuflow lab fume hoods direct supportive airflow from the aerodynamically shaped airfoil cills of the side walls and table edges into the internal workspace, preventing turbulence and stabilizing the inflow. This optimized airflow design allows for a reduction in exhaust air volume by up to one-third, while maintaining complete operational safety. The airflow rate is thus reduced to 270 m³/h per meter, resulting in significant energy savings.

Whisper-Quiet due to State-of-the-Art Technology

Reducing the air volume offers benefits beyond energy savings. A notable advantage is the significant reduction in noise emissions, creating a quieter environment conducive to focused and effective work at the laboratory fume hood, regardless of the laboratory's size.

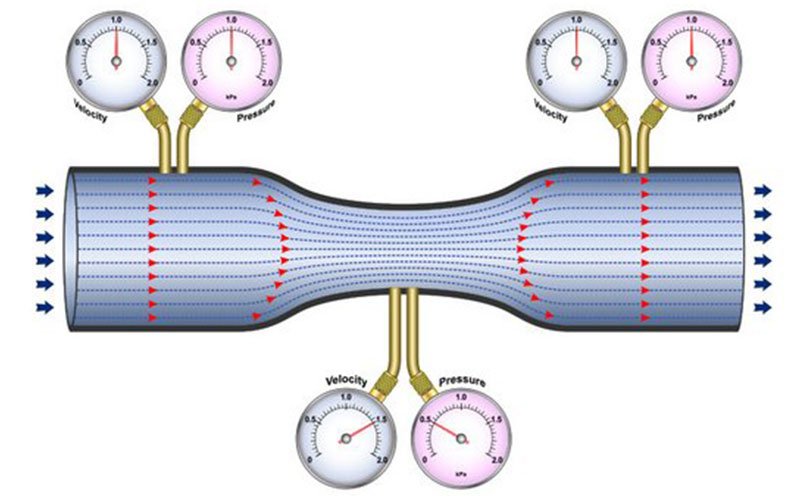

Flow-optimized volume flow measurements, utilizing the Venturi principle, are integrated into the precisely coordinated control technology, decreasing the sound level by up to 10 dB(A). This design ensures exceptionally quiet operation.

Variable and Individual, Thanks to Their Modular Design

Thanks to their modular system, Waldner fume hoods can be ideally adapted to the dimensions and conditions within your laboratory. The following laboratory fume hood versions are available:

Waldner laboratory fume hoods are available in the following widths based on a 300 mm grid:

- 1,200 mm

- 1,500 mm

- 1,800 mm

- 2,100 mm

- 2,400 mm

The internal volume is maximised by integrating the drip sink in the rear and/or side walls. Moreover, the connection height of the fume hoods can be reduced to 2,570 mm for rooms with low ceilings.

The interchangeable service modules are integrated in the rear and side walls of the fume hoods. The configuration for the supply of sanitary and electrical media can be flexibly adapted to customer requirements. This allows the modules to be perfectly tailored to your needs.

Worktops and coatings for laboratory fume hoods can be manufactured from materials ideally suited to your specific application and intended use:

- Melamine resin facing / post-forming

- Polypropylene

- Solid (grade) laminate, Trespa Toplab+ solid (grade) laminate

- Epoxy

- Stainless steel

- Stoneware-composite worktop

- Glass

The materials used for the internal lining, along with the design of the fume hood, determine its potential applications. Suitable stoneware is used for the internal lining of special application fume hoods, especially when handling sulfuric acid, hydrochloric acid, or aqua regia. Additionally, other materials are available for different applications.

Self-supporting underbench units provide storage for equipment and chemicals. They can be customized for acids, alkalis, solvents, or cooling units, depending on specific requirements.

Fume cupboards with rear wall installation feature side posts that are only 25 mm wide, ensuring maximum access width. The control panel beneath the worktop is angled towards the user, promoting optimal ergonomic posture during work.

Fume cupboards with side installation incorporate control units within 100 mm-wide service panels positioned at the sides. The corresponding extraction outlets and sinks are seamlessly integrated into the side walls.

Waldner SI 3 Steel-type fume hoods for the laboratory are also available as side-installed steel fume hoods. If required, the internal lining can be made from polyresin, solid-grade laminate, polypropylene, or stainless steel.

Insights: Waldner Secuflow Vision Laboratory Fume Hood

Mobile Laboratory Fume Hoods for Greater Flexibility in the Laboratory

Secuflow Vision: Redefining Ergonomics

Transparency in design and ergonomics is becoming increasingly important in meeting the demands of future laboratories. The Waldner Secuflow Vision fume hood stands out with its array of intelligent features:

Lab technicians come in different sizes, yet adjustable work surfaces—common for desks—are often missing in laboratory environments. With electric height adjustment, the working height can now be continuously adapted to the user. Up to four individual heights can be saved and recalled at the touch of a button, ensuring an individual ergonomic posture in seconds.

In addition to its large glazed panels, the Waldner Secuflow laboratory fume hood stands out with its inclined front, which enhances ergonomics and simplifies working conditions. The Secuflow Vision allows operation with partially open side sliding windows, reducing airflow, saving energy, and increasing safety. The fume hood is designed with four individual panels that are narrow enough for users to reach past them from both sides. These panels provide protection against spraying liquids and even explosions.

The retractable keyboard facilitates digital documentation of workflows and can be fully stowed away when not in use. Its three-dimensional adjustability allows alignment to suit the user and working conditions, ensuring effortless, joint-friendly operation.

The Secuflow Vision laboratory fume hood ensures that essential consumables are always within reach. A multifunctional holder for containers or pipettes can be mounted inside the workspace, minimizing movement and reducing unnecessary reach in front of the open fume hood window. This helps maintain unobstructed airflow and enhances safety.

In addition to its air guidance function, the sash handle is designed for exceptional user convenience. It can be effortlessly unlocked with just one hand, while a touch function activates automatic opening. The motorized slider glides smoothly and also closes automatically, with a light barrier detecting obstacles and pausing the closing process for safety.

The integrated foot switch, positioned at plinth height, is especially useful when lab technicians have their hands full with materials or equipment. It allows hands-free operation of the sash, enhancing safety while reducing unnecessary to-ing and fro-ing.

The integrated glove dispenser on the Secuflow Vision lab fume hood is both practical and efficient. Laboratory gloves are neatly stored in a dedicated holder within the underbench cabinet, allowing quick and hygienic one-handed glove changes. A paper towel dispenser is also integrated into the underbench unit, ensuring easy access to clean paper towels with just one hand.

Curious?

Are you looking to purchase a laboratory fume hood or planning a large laboratory project? Whether you need a compact bench-mounted fume hood, an EN7 chemical fume hood or mobile laboratory fume hoods: we'll develop a custom-made solution for you. Just ask us!

These might also interest you